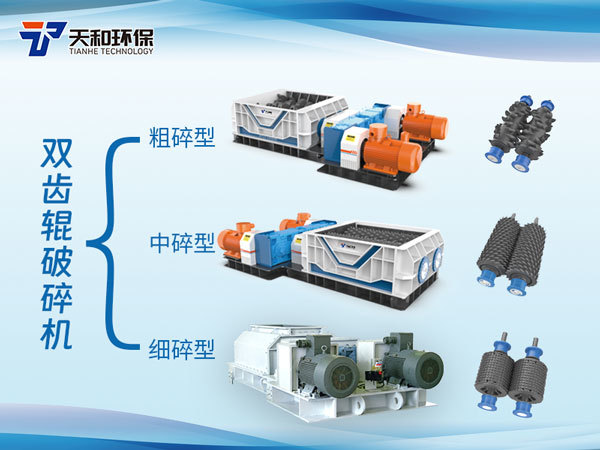

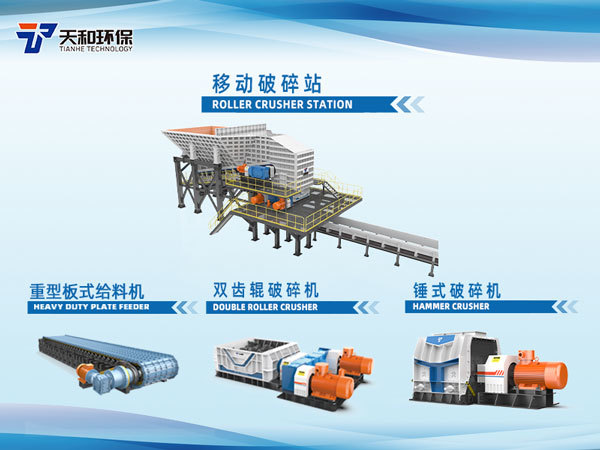

Double-tooth roller crusher selection guide: precise matching, efficient operation

Release time:

2025-07-16

Tianhe Environmental Protection has been deeply involved in the mineral crushing field for over 20 years, and with experience from 1400+ projects, we provide you with a detailed selection guide for double-toothed roller crushers.

In industrial and mining enterprise production, selecting suitable crushing equipment is crucial for improving resource utilization and reducing waste. Double-Tooth Roller Crusher Due to its unique shearing, extrusion, and tensile crushing principle, it performs excellently in processing medium-hard materials such as coal and limestone.

However, with numerous models of double-tooth roller crushers on the market, how to conduct scientific and reasonable selection has become a key issue. Tianhe Environmental Protection has been deeply involved in the mineral crushing field for over 20 years, and combined with experience from 1400+ projects, we provide you with a detailed selection guide for double-tooth roller crushers.

Clarify Production Needs

First, clarifying your production needs is the basis for selection. Different application scenarios have different requirements for crushing equipment, mainly considering the following aspects:

Material Properties: Understand the hardness, viscosity, humidity, and particle size distribution of the material to be processed. For example, when processing materials with high water content, a model with anti-blocking function should be selected.

Production Capacity: Determine the required processing capacity (tons/hour) according to the needs of the production line. Different models of double-tooth roller crushers have different processing capacity ranges, ensuring that the selected equipment can meet actual needs. Output Particle Size:

The final product particle size requirements directly affect the configuration and adjustment method of the crusher. Some models offer multiple adjustment methods, such as eccentric cups, screw rods, and hydraulic methods, to achieve precise control. Consider Equipment Performance

After clarifying the basic needs, the specific performance indicators of the equipment need to be considered next:

Lump Rate and Over-Crushing Rate: High lump rate and low over-crushing rate are important standards for measuring crushing effect. High-strength double-tooth roller crushers use specially designed crushing tooth structures, especially suitable for application scenarios with strict requirements on finished product particle size.

Wear Resistance and Service Life: The choice of crushing tooth material

is directly related to the durability of the equipment. Tianhe Environmental Protection's double-tooth roller crushers use Baosteel wear-resistant alloy ( HRC45-55), with impact toughness reaching 38Kg·m/cm², and a service life 2-3 times that of common industry products. Maintenance Convenience

Daily maintenance and upkeep of the equipment are also factors to consider during selection. Advanced vibration damping structures, couplings that absorb instantaneous impact, and various mechanical and electrical protection measures greatly improve the reliability of equipment operation, reduce failure points, and facilitate maintenance. : Adaptability to Working Environment

In addition to the above technical parameters, the working environment of the equipment should also be considered:

Installation Conditions: Evaluate the site's spatial layout and infrastructure to select a suitable model for installation. For example, when installing in underground tunnels, equipment with a compact structure and small size should be selected.

Environmental Factors: Considering the impact of dust, water, oil, etc., on the equipment, select models with good sealing systems to ensure that the equipment can operate stably even in harsh environments.

Conclusion

The selection of double-tooth roller crushers is a comprehensive process that requires a comprehensive analysis from multiple perspectives, including material properties, production capacity, output particle size, equipment performance, working environment, and company strength. Tianhe Environmental Protection, with its rich experience and advanced technology, provides users with a series of high-performance double-tooth roller crushers. Choosing crushing equipment that suits your needs can help enterprises achieve more efficient and intelligent production goals.

双齿辊破碎机的选型是一个综合考量的过程,需要从物料特性、生产能力、出料粒度、设备性能、工作环境以及公司实力等多个角度进行全面分析。天和环凭借其丰富的经验和先进技术,为用户提供了一系列高性能的双齿辊破碎机,选择适合自身需求的破碎设备,才能帮助企业实现更高效、更智能的生产目标。

Previous

Recommend News