Screen first, then crush—achieving twice the result with half the effort: Tianhe Environmental’s screening and crushing station ushers in an era of lean processing.

Release time:

2026-01-21

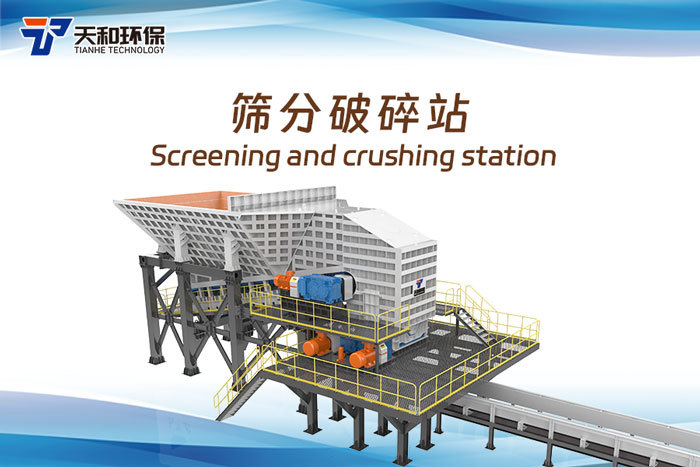

The Tianhe Environmental Protection Screening and Crushing Station integrates processes such as material receiving, feeding, crushing, conveying, screening, and temporary storage. It primarily comprises a buffer hopper, a heavy-duty apron feeder, a vibrating feeder, a double-tooth roll crusher, a vibrating screen, a complete electrical system, a monitoring system, and associated steel structure platforms. This station boasts advantages including a compact structure, a short installation and commissioning period, high mobility, and a high degree of intelligence.

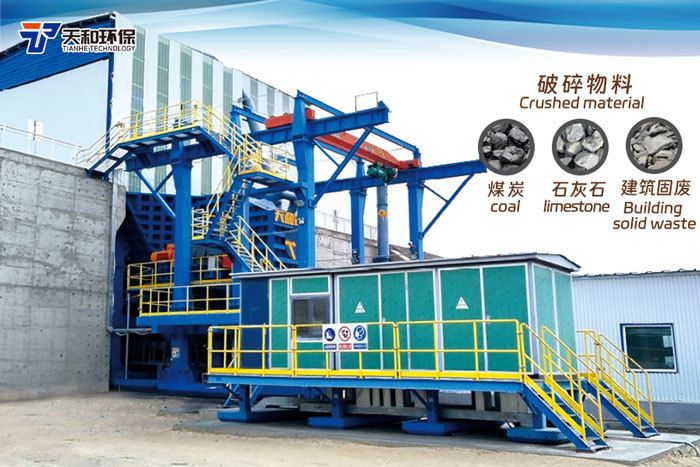

When dealing with materials of diverse compositions and varying moisture levels—such as coal, limestone, construction waste, oil shale, and clay—many companies have found that the problem isn't a lack of crushing capacity; rather, it's that "materials that shouldn't be crushed are being crushed anyway." Over-crushing not only wastes energy but also reduces the yield of high-value bulk materials. How can we achieve the right balance—“crush what needs to be crushed, and leave intact what should remain untouched”? The Tianhe Environmental Protection Screening and Crushing Station offers an industry-leading, more economical and sustainable approach through its process logic of “screening first, then crushing.”

Tianhe Environmental Screening and Crushing Station Integrating processes such as material receiving, feeding, crushing, conveying, screening, and temporary storage, this system primarily comprises a buffer hopper, a heavy-duty apron feeder, a vibrating feeder, a double-tooth roll crusher, a vibrating screen, a complete electrical system, a monitoring system, and associated steel-structure platforms. It boasts advantages including a compact structure, a short installation and commissioning period, high mobility, and a high degree of intelligence.

The screening and crushing station places the vibrating screen at the front end. Raw materials first enter the screening unit, where those meeting the required particle size are directly diverted to the finished-product bin, while only the oversized particles proceed to the crushing stage. This design significantly reduces the amount of ineffective crushing, lowers equipment load and energy consumption, and simultaneously improves the block-forming rate. — Particularly suitable for the production of recycled aggregates or calcined raw materials that have specific particle shape requirements.

The core crushing module can be flexibly equipped with either a double-tooth roll crusher or a hammer crusher, depending on the material properties. For sticky, wet, and easily clogged industrial byproducts (such as petroleum coke and bauxite), the double-tooth roll crusher operates at low speed to shear the material gently and prevent blockages. For conventional brittle materials, an efficient hammer crusher is employed to ensure high processing capacity. The entire plant integrates a heavy-duty plate feeder, multi-stage conveyor belts, and an intelligent control system, enabling seamless coordination throughout the entire process.

Supports both fixed installation and mobile deployment, catering to diverse application scenarios such as mines, construction waste sites, and temporary stockpiles. The enclosed structure, combined with dust suppression measures, meets environmental protection standards. The PLC system supports remote monitoring, enhancing management efficiency.

In today’s era, as resource utilization moves toward greater refinement, true efficiency does not come from... “Aggressive and relentless,” yet rooted in the rational optimization of processes. The Tianhe Environmental Protection Screening and Crushing Station, with the wisdom of a single “screening” step, saves ten percent of energy consumption and unlocks greater value.

Recommend News