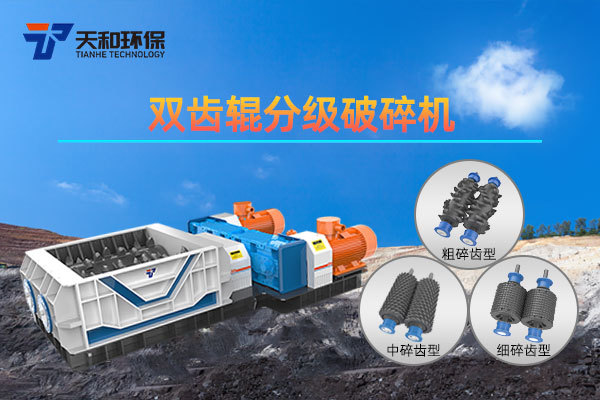

Double-tooth roller crusher: A rational choice for efficient crushing in open-pit coal mines.

Release time:

2026-02-04

Tianhe Environmental Protection has been deeply engaged in the mineral crushing industry, and its double-tooth roller crusher—with its solid performance—is becoming the preferred equipment for coarse and medium crushing of raw coal in open-pit coal mines.

In the continuous production system of large-scale open-pit coal mines, the crushing stage is like... “The throat”—it must be able to both swallow large chunks of raw coal and spit out qualified-sized particles. Faced with multiple objectives—high productivity, operational stability, and low energy consumption—more and more mines are turning their attention to double-tooth roll crushers, which feature reliable structures and cost-effective operation.

Tianhe Environmental Protection has been deeply engaged in the mineral crushing industry, and its double-tooth roller crusher—with its solid performance—is becoming the preferred equipment for coarse and medium crushing of raw coal in open-pit coal mines.

One machine handles the load, ensuring a steady and high-yield pace.

Open-pit mines feature large-sized raw coal lumps and high production volumes, placing stringent demands on the continuous operational capability of equipment. The Tianhe Environmental Protection Double-Tooth Roll Crusher adopts a design in which two rollers rotate toward each other, achieving efficient liberation through a combined shearing and compressive force, with outstanding single-machine processing capacity. Compared to conventional impact-type equipment, it operates more smoothly and is less likely to shut down due to transient overloads, effectively supporting the mining industry’s daily crushing demand of up to 10,000 tons.

Adjustable particle size, enhancing coal quality.

Modern coal utilization emphasizes precise control of particle size. Tianhe Environmental Protection Equipment supports hydraulic stepless adjustment of roller gaps, enabling flexible setting of the discharge particle size according to downstream processing requirements. During the crushing process, coal fractures along its natural cleavage planes, resulting in finished products that are predominantly cubic in shape, with significantly reduced content of needle-like and flaky particles as well as coal dust. This not only increases the yield of lump coal but also reduces storage and transportation losses and problems associated with incomplete combustion.

Low consumption, long lifespan, and optimized total lifecycle costs.

The equipment operates at low speed with high torque, and its energy consumption is lower than that of high-speed impact crushers. The crushing teeth are made from a wear-resistant alloy material based on the bainite structure, offering a service life that exceeds that of commonly used products in the industry. 2-3 times the capacity, coupled with an automatic overload-release protection mechanism, effectively cushions impacts when encountering metal objects or hard rock, thereby preventing damage to the main spindle or bearings. It features a long maintenance cycle and convenient replacement of spare parts, significantly reducing long-term operation and maintenance costs.

Structurally reliable, unafraid of complex operating conditions.

Even when processing raw coal containing small amounts of gangue and with fluctuating moisture levels, the Tianhe Environmental Protection double-tooth roller crusher can still maintain stable output. The machine features a compact structure and has low requirements for the installation foundation, making it ideal for rapid deployment in open-pit mines. Its enclosed design, combined with dust-control measures, further enhances its performance in dusty environments.

In today’s pursuit of both efficiency and sustainability, the Tianhe Environmental Protection Double-Tooth Roller Crusher responds to real-world operating conditions with rational design, helping open-pit coal mines achieve... The upgrade from “Capable of Breaking” to “Excellent at Breaking”

Previous

Recommend News