Intelligent sorting and crushing machine for complex minerals: Promoting the upgrading of coal mining machinery and equipment

Release time:

2025-08-06

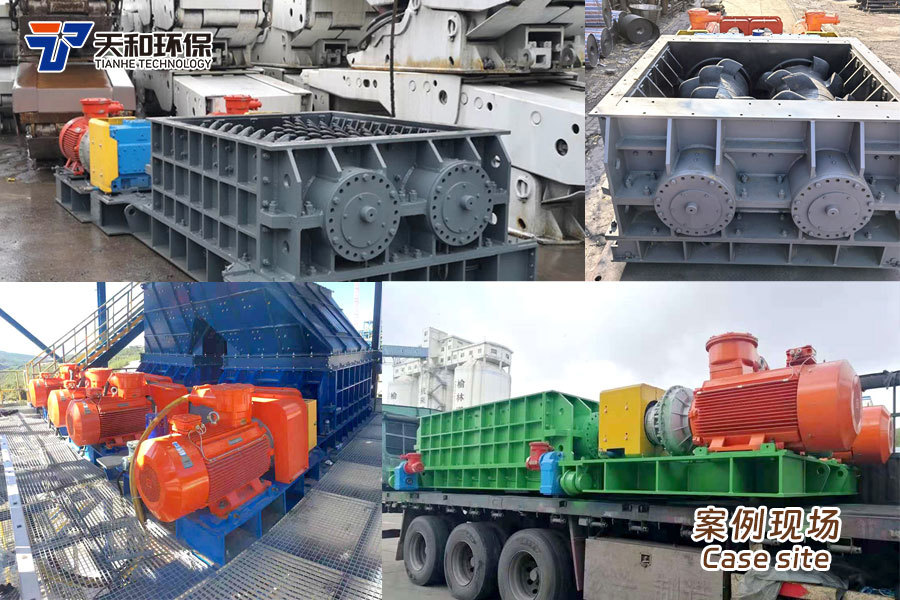

In modern coal industry, traditional crushing equipment often struggles to cope with the complex and variable ore composition and increasingly stringent environmental requirements. To this end, Tianhe Environmental Protection has launched an intelligent classification crusher for complex minerals, which, with its innovative design concept, stable technical performance and wide applicability, is promoting the upgrading of coal mining machinery equipment.

In modern coal industry, traditional crushing equipment often struggles to cope with complex and variable ore compositions and increasingly stringent environmental requirements. To address this, Tianhe Environmental has launched the intelligent complex mineral grading crusher, which, with its innovative design concept, stable technical performance, and wide applicability, is driving the upgrading of coal mining machinery equipment.

High-efficiency grading capability

Precise particle size control The intelligent complex mineral grading crusher uses multiple distance adjustment methods (eccentric cup, screw, hydraulic), allowing flexible adjustment of the discharge particle size according to actual needs. Whether it is coarse crushing, medium crushing, or fine crushing, precise control can be achieved to ensure that each batch of materials meets process requirements.

Optimized material handling The equipment uses a spirally arranged crusher tooth design, allowing materials to enter the crushing chamber evenly, reducing over-crushing, significantly improving the lump rate, maximizing resource utilization, and reducing waste.

Diversified crushing modes

Adaptable to materials of different hardness This equipment can handle various minerals from low to medium hardness, including limestone, construction waste, oil shale, etc., and has wide applicability, especially suitable for complex working conditions in coal mines.

Multi-stage crushing system Through graded crushing, materials can be crushed multiple times to ensure that the particle size after each stage of crushing meets process requirements, further improving product quality and meeting the market's high demand for high-quality products.

Adaptable to harsh working conditions

Wear-resistant materials The crusher teeth are made of bainite wear-resistant alloy (HRC45-55), with impact toughness reaching 38Kg·m/cm², featuring high strength and high wear resistance, suitable for harsh working environments, ensuring long-term stable operation of the equipment.

Sealed design The equipment adopts a split box structure and an advanced sealing system, effectively separating the bearing position from the crushing chamber, preventing dust, water, and oil from entering the bearing chamber, protecting key components, and extending the service life of the equipment.

Wide application, promoting industry upgrading

Coal mining Suitable for crushing and processing various minerals such as coal and metal ores, helping enterprises improve production efficiency, reduce costs, and promote technological progress in the coal mining industry.

Industrial waste treatment It can be used to process construction waste, oil shale, and other industrial waste, realizing resource reuse and promoting the development of a circular economy.

Conclusion

The Tianhe Environmental intelligent complex mineral grading crusher, with its innovative design concept, stable technical performance, and wide applicability, has become an ideal choice for enterprises to improve production efficiency and reduce operating costs. It not only promotes the upgrading of coal mining machinery equipment but also helps mining enterprises move towards a greener and more intelligent development path.

Recommend News