In the field of limestone crushing, why has the double-tooth roller crusher become the new favorite in the industry?

Release time:

2025-08-27

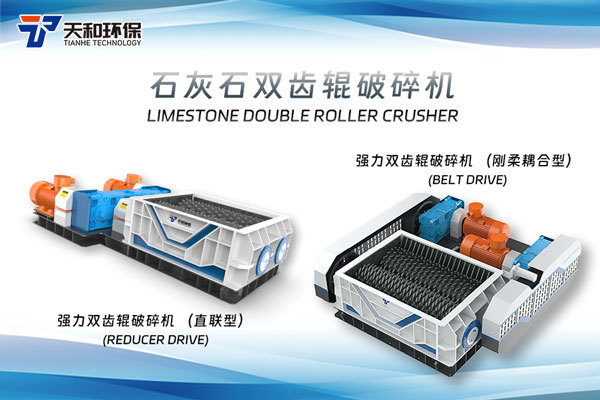

The Tianhe Environmental Protection double-toothed roller crusher adopts a composite crushing method combining shearing, extrusion, and stretching. With center distance adjustment technology and diversified toothed roller structures, the material particle size can be precisely controlled, achieving a lump rate of up to 90%. This feature is especially critical for quicklime calcination or calcium carbide production requiring stable particle size, helping to improve calcination efficiency and product quality.

Today, with limestone widely used in building materials, metallurgy, chemical industry, and other fields, the efficiency and quality of the crushing stage directly affect the stability of subsequent processes and resource utilization.

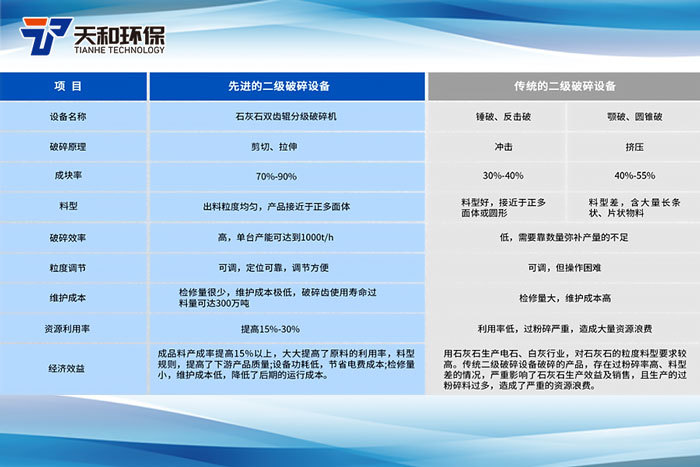

Facing pain points such as traditional crushing equipment prone to over-crushing, uneven particle size, high energy consumption, and frequent maintenance, more and more companies are turning their attention to a solution with greater technological advantages. —— Double-Tooth Roller Crusher 。

More Scientific Crushing Principle, More Precise Particle Size Control

Unlike hammer or impact crushers that rely on impact force, the double-tooth roller crusher uses a composite crushing method combining shearing, squeezing, and stretching. With center distance adjustment technology and diversified tooth roller structures, the particle size of materials can be precisely controlled, achieving a lump rate of up to 90%. This feature is especially critical for lime calcination or carbide production requiring stable particle size, helping to improve calcination efficiency and product quality.

Strong Adaptability, More Stable Operation

Limestone raw materials often contain clay, moisture, or hardness fluctuations, which easily cause equipment blockage or accelerated wear. Tianhe Environmental's double-tooth roller crusher improves adaptability to complex materials by optimizing crushing tooth structures (such as active teeth, sleeve types, etc.) and spiral tooth arrangement. Meanwhile, the equipment is equipped with hydraulic opening and closing devices and overload protection systems, facilitating maintenance and timely response in abnormal situations to ensure continuous and stable production line operation.

Wear-Resistant and Durable, Reducing Overall Costs

To address the high wear problem in limestone crushing, Tianhe Environmental uses self-developed bainitic wear-resistant alloy materials for key components (HRC45-55, impact toughness 38Kg·m/cm²), with a service life 2-3 times that of industry-standard products. The split box structure and sealing design effectively prevent dust from entering the bearing chamber, extending the life of core components, reducing downtime for maintenance, and lowering the overall operating costs of the equipment from a long-term perspective.

Intelligent Design, Supporting Green Production

The equipment features a compact overall structure and a closed design combined with dust reduction measures to effectively control dust dispersion during operation. Paired with the intelligent cloud management system for the crusher, which integrates data collection, supervision, control, early warning, alarm, and diagnosis functions, it provides comprehensive management of the equipment's operating status and offers customers professional intelligent solutions.

Conclusion

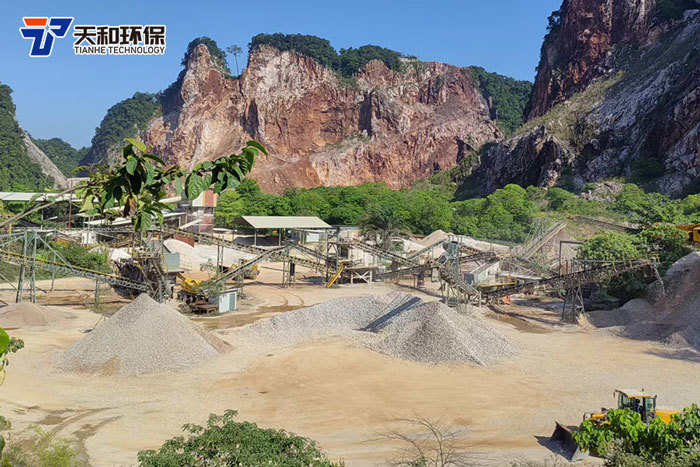

In the pursuit of efficiency, energy saving, and sustainability today, the double-tooth roller crusher, with its scientific crushing mechanism and stable operation performance, is gradually becoming the mainstream choice for limestone processing. Tianhe Environmental has been deeply engaged in the crushing field for many years; its double-tooth roller crusher has been stably applied in multiple projects, providing users with reliable crushing solutions, making every crushing process closer to the ideal "degree."

Recommend News