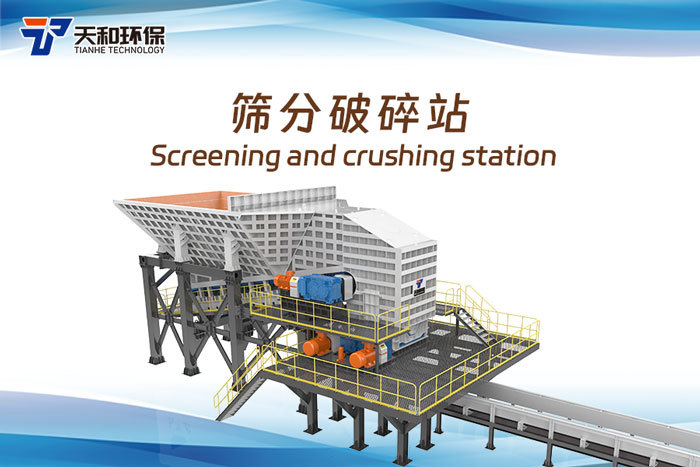

Tianhe Environmental Protection Screening and Crushing Station, opening a new chapter of efficient crushing

Release time:

2025-09-12

The Tianhe Environmental Protection Screening and Crushing Station integrates processes such as receiving, feeding, crushing, screening, conveying, and temporary storage into a complete mobile or fixed operation unit. The equipment combines a heavy-duty plate feeder, double-tooth roller crusher, vibrating screen, buffer silo, and conveying system to achieve "one-stop" processing.

In fields such as mining, metallurgy, and solid waste treatment, material screening and crushing are key steps in the production process. Faced with complex working conditions, variable raw materials, and increasingly stringent environmental requirements, traditional decentralized equipment combinations can no longer meet the demands for efficient, stable, and low-consumption production.

How to achieve efficient and intelligent operations from raw material processing to finished product output? Tianhe Environmental Screening and Crushing Station It is providing efficient and reliable solutions for modern industry through integrated design and stable performance.

Highly integrated to create an efficient production chain.

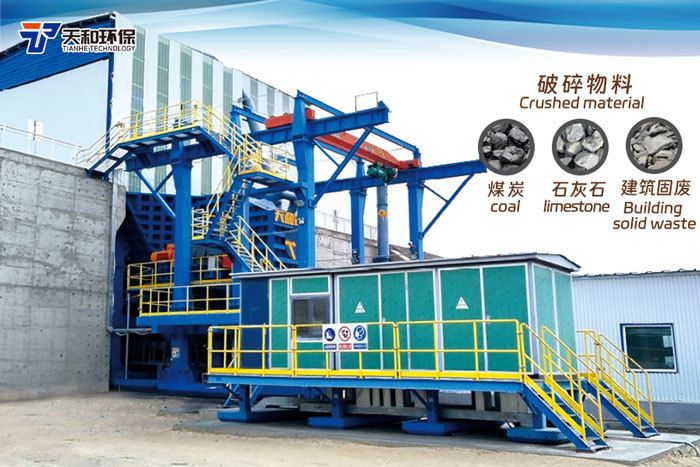

The Tianhe Environmental Screening and Crushing Station integrates receiving, feeding, crushing, screening, conveying, and temporary storage processes into a complete mobile or fixed operation unit. The equipment combines heavy-duty plate feeders, double-toothed roller crushers, vibrating screens, buffer hoppers, and conveying systems to achieve "one-stop" processing. Whether limestone, coal, construction solid waste, or oil shale, it can efficiently complete graded crushing, significantly improving overall operational efficiency, reducing intermediate transfer steps, and lowering energy consumption and labor costs.

Scientific process to optimize resource utilization.

Adopting a scientific process of "screening first, then crushing." The pre-screening system effectively separates qualified particle sizes, avoiding over-crushing, increasing lump rate, and reducing fine powder generation. The crushing unit uses Tianhe Environmental's independently developed double-toothed roller crusher, based on shear and extrusion principles, producing uniform particle size and regular shape, meeting the high requirements of subsequent production for raw materials and improving resource utilization.

Intelligent control to ensure stable operation.

The entire station is equipped with a PLC automation control system, supporting remote monitoring, operation parameter adjustment, and fault warning to achieve centralized management. Operators can monitor equipment status in real-time via a touchscreen, improving operation and maintenance efficiency. The system integrates multiple safety mechanisms such as blockage alarms, overload protection, and stall detection to effectively prevent equipment abnormalities, ensure continuous and stable operation, and reduce unplanned downtime.

Flexible deployment to adapt to diverse scenarios.

The screening and crushing station adopts a modular mobile/fixed design, allowing quick relocation and flexible deployment, suitable for various complex environments such as open-pit mines and demolition sites. The mobile model can directly go to the operation site to achieve "on-site processing and local utilization," greatly reducing transportation costs and secondary pollution risks.

Tianhe Environmental has been deeply involved in the mineral crushing field for many years, providing reliable crushing solutions to numerous users. Its screening and crushing stations have been operating stably in multiple projects for years, making every crushing process closer to the ideal "degree" and enhancing the production efficiency of every customer.

Recommend News