Limestone "Smart" Manufacturing New Engine: Tianhe Environmental Protection Screening and Crushing Line Empowers Efficient Production

Release time:

2025-09-03

The Tianhe Environmental Protection Screening and Crushing Line adopts an integrated layout, combining a plate feeder, PE series jaw crusher, double-tooth roller crusher, grading screen, and fine particle shaping machine to achieve coordinated operation from raw material input to finished product output. The modular design facilitates transportation and installation, making it especially suitable for plants with complex terrain or limited space, significantly shortening construction cycles and improving overall operational efficiency.

In industries such as building materials, metallurgy, and chemical engineering, limestone serves as an important basic raw material. Its processing quality directly affects the performance and production efficiency of the end products. Traditional limestone processing often uses multiple dispersed pieces of equipment, resulting in long processes, high energy consumption, unstable particle size control, and complex maintenance.

How to achieve efficient, stable, and low-consumption processing from raw ore to finished product? Tianhe Environmental Protection has launched a limestone screening and crushing line that, with an integrated and intelligent design concept, provides an all-in-one solution for the industry.

Integrated Design, Optimized Process Flow

Traditional limestone crushing relies heavily on dispersed equipment combinations, leading to long processes, large footprints, and low efficiency. Tianhe Environmental Protection's screening and crushing line adopts an integrated layout, combining plate feeders, PE series jaw crushers, double-tooth roller crushers, classification screens, and fine particle shaping machines to achieve coordinated operation from raw material input to finished product output. The modular design facilitates transportation and installation, especially suitable for plants with complex terrain or limited space, significantly shortening construction cycles and improving overall operational efficiency.

Screen First, Then Crush, Improving Resource Utilization

The production line adopts a scientific process of "screening first, then crushing." Raw ore first enters a vibrating screen for pre-screening, directly separating materials that meet particle size requirements, with only the oversized portion entering the crushing stage. This design effectively avoids repeated crushing of qualified materials, significantly reduces over-crushing, improves lump rate, lowers crusher load, extends equipment lifespan, reduces energy consumption and wear from the source, and enhances comprehensive resource utilization.

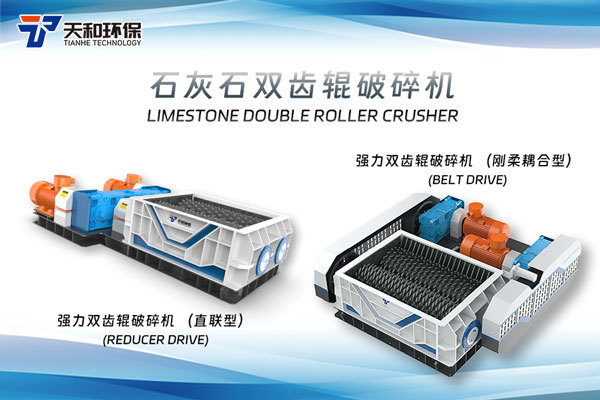

Double-Tooth Roller Crushing Makes Every Crush Closer to Ideal "Degree"

The core crushing unit uses Tianhe Environmental Protection's double-tooth roller crusher, based on the composite principles of shearing, squeezing, and stretching. Unlike traditional impact crushing, the process is gentler, producing uniform particle size and regular particle shape. The equipment can be configured with active tooth or clamping tooth crushing structures according to different working conditions, suitable for stable processing of medium-hardness limestone, especially for processes with strict feed size requirements such as quicklime calcination and calcium carbide production.

Green Operation, Supporting Sustainable Development

The production line adopts a closed structure design combined with a spray dust suppression system, effectively controlling dust dispersion during operation and improving the on-site working environment. The equipment operates with low noise and optimized energy consumption, aligning with green factory construction goals. Through efficient crushing and resource reuse, it helps enterprises achieve low-carbon, environmentally friendly, and sustainable production objectives.

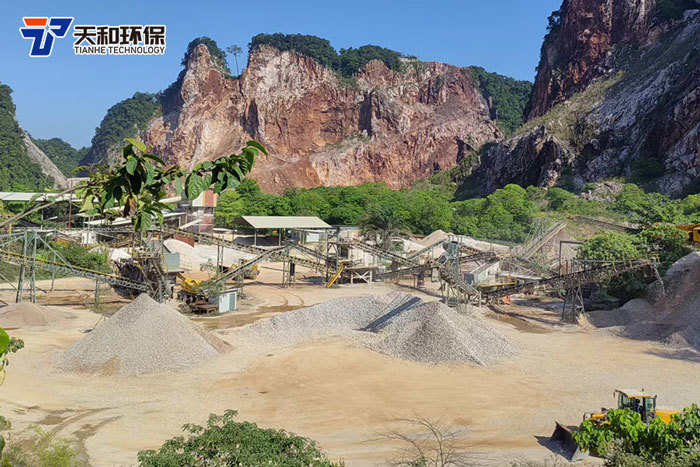

With mature technology accumulation and rich project experience, Tianhe Environmental Protection's limestone screening and crushing line has achieved stable operation in multiple regions, helping enterprises optimize production processes, improve resource utilization, and realize the joint development of economic and environmental benefits in limestone mining!

Recommend News